An important aspect of Numatex’s January 31, 2012, patent application is the absolute ability to locate any and every fault in the ground using NMR, to determine the direction of each fault, and the age rocks affected by the faulting, all by NMR. While it is common knowledge within the oil and gas industry larger faults are easily seen by the naked eye, visible from the air, and detected by seismic, our twenty-five years of experience in the industry has made it clear many of the smaller unseen faults have never been detected or mapped, especially UNDER FLAT GROUND. We have observed hundreds of oil and gas wells which have been drilled into faults or adversely affected by faults the operators had no knowledge existed. Whereas Kentucky is notorious for unseen faults, so is every other area of the United States.

Thomas Wiley’s first observation of a fault by NMR occurred in 1994 in Spencer County, Indiana, but he did not know what he had seen. His second observation occurred in Parker County, Texas, near Weatherford. Even though he still did not know what he had seen, it was notable that the activity was exactly the same as that which occurred in Indiana, providing a clue by demonstrating a conformity in disparate locations based on physics. When Numatex drilled its first well in Daviess County, Kentucky, near Maceo in 1999, the same activity occurred on all four sides of that unsuccessful well, confining the drilling location to a ten-acre square faulted on all four sides. Its low permeability all the way down caused Thomas Wiley to conclude that faulting’s affects were being undeniably illustrated.

Beginning in 1999, Mr. Wiley’s experiments led to the ability not only to read a fault, but to determine which age rocks are affected by faulting. In the Illinois Basin, those ages are Pennsylvanian at the surface, followed by Mississippian, Devonian, Silurian, Ordovician, Cambrian, and Pre-Cambrian. As part of his research, Mr. Wiley had to find out whether the NMR activity observed in the Illinois Basin and near Weatherford, Texas, pertaining to faults would occur with conformity elsewhere. He learned in Texas, Louisiana, Arkansas, Missouri, Tennessee, Mississippi, Alabama, Florida, Virginia, West Virginia, Pennsylvania, New Jersey, Ohio, Michigan, Montana, Wyoming, Colorado, and California AND OFFSHORE that the NMR fault recognition is universal.

As part of that research, Mr. Wiley has observed every fault between Owensboro, Kentucky, and St. Louis, Missouri, along Interstate 64 and every fault between the Red River and Ft. Worth, Texas, each helping explain oil production and drilling depths in those areas. His first opportunity for offshore testing occurred in 2005 with the same physical results over 1,000 feet of water. Conclusions as to faulting as the cause phenomenon is based on research of existing well records, substantiated by structural log anomalies, poor production, dry holes, and stories of drill pipe resistance and ejection.

Applying NMR technology to fault detection leads to mapping faults in areas no one has ever mapped either by isopachs, aerial photography, or seismics, because many faults occur under flat ground or very gently rolling ground. On the other hand, gently rolling ground, hills, streams or rivers are not always indication of a fault, although they can be found nearby. For example: one would believe major rivers flow above faults. Mr. Wiley has tested many rivers for faulting and found major faulting on either side of the rivers’ paths, including a major fault on the Illinois side of the Mississippi River near St. Louis and a major fault on the west side of the Wabash River in Illinois. Mr. Wiley’s observation of fault patterns has also yielded detection of oil traps on one side, hugging the fault for long distances, while observing tight permeability on the other. The technology detects the conditions suggesting a fault before it is ever approached, based on nuclear magnetic influences, which would also influence drilling decisions.

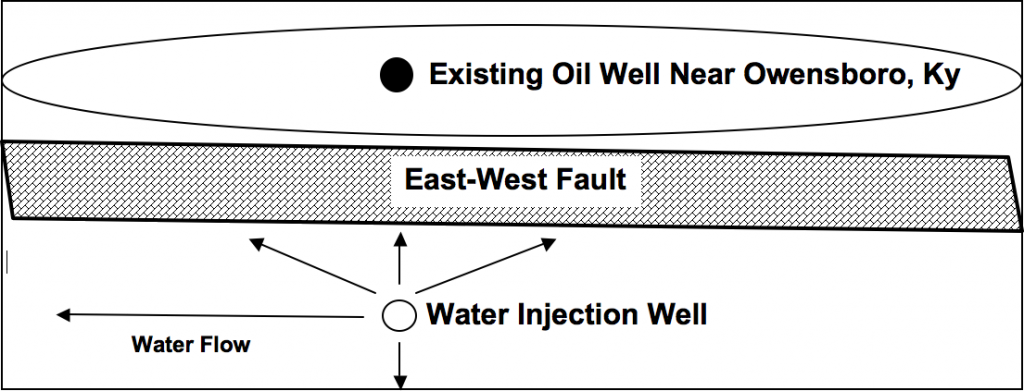

Fault recognition not only affects plans for drilling a single oil or gas well, but an understanding of fault patterns in the area is an invaluable tool towards planning area-wide well control, injection planning, and fracking decisions. An incident occurred in Daviess County, Kentucky, where an operator was complaining that his waterflood had never “kicked in.” An NMR fault test revealed in all of thirty minutes that his injection well was separated from his producing well by a fault, causing his injection water to go far afield without benefitting his oil well. The following illustrations demonstrate how placement of injection wells by lack of faulting information can either benefit your injection program or cause it to be wasted money, as was found near Owensboro, Kentucky.

THE FOLLOWING ILLUSTRATION DEMONSTRATES HOW A FAULT INTERFERES WITH THE WATER INJECTION WELL’S ABILITY TO PUSH OIL TOWARD THE EXISTING OIL WELL – WHY IT HAD “NEVER KICKED IN.” NMR DETECTED THE FAULT AND ITS DIRECTION IN ALL OF THIRTY MINUTES, EXPLAINING HOW WATER IS GOING IN EVERY DIRECTION EXCEPT TOWARD THE OIL ZONE. WE CAN DO THE SAME THING FOR YOU BY HELPING YOU DETERMINE WHERE TO INJECT YOUR WATER FOR ITS MAXIMUM POSITIVE EFFECT ON DRIVING YOUR OIL.

We ourselves observed on a lease we purchased in McLean County, Kentucky, an old injection well having been located on a fault. We observed water and oil seeping back to the ground and into a creek, being caused in our opinion by the ground’s rejection of the water. When the nearby injection pump was turned off, the seepage stopped. That injection well was eventually plugged, permanently solving the problem. That same decision can solve many potential pollution issues around the world.

People around Youngstown, Ohio, have observed an unusual proliferation of minor earthquakes in recent years and blame gas fracking. As part of a plan to head off earthquakes caused by fracking, the State of Ohio is contemplating a requirement that all oil and gas operators submit a map of all faulting on their leases when applying for a drilling permit, the assumption being that choices made as to fracking locations may adversely affect unseen faults and cause earthquakes. While local operators complain such technology does not exist and would be cost-prohibitive, Numatex can provide those maps in Ohio and anywhere else with 100% accuracy as to depth and direction of any fault in the area. Our affordable price for finding and mapping your faults can save you millions of dollars in misplaced drilling locations, potential pollution, and potential liabilities.

Finally, what is it worth to you to know when your planned oil or gas well may be located on a fault or near enough to adversely affect your permeability? Wouldn’t you rather put your money to work for positive and ultimate production? Call Numatex.